Years in Business

-

Company

The CompanyResourceImagination Meets, Implementation

9+

9+ 1600+

1600+Projects Delivered

600+

600+Client Relationships

20+

20+Countries Served

-

Services

Our Services

- Software Development

- Web Development Services

- IT Services

- Security Engineering

- Cloud & Hosting Services

- Testing & QA

- Digital Marketing

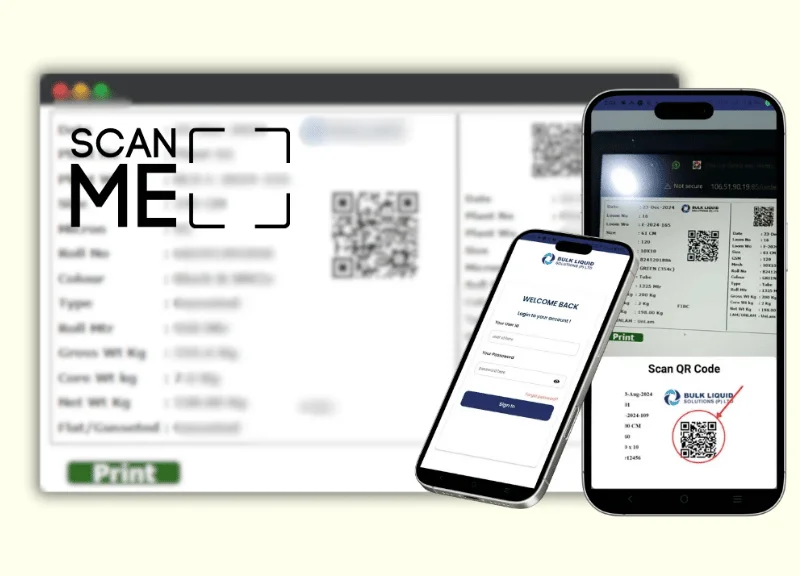

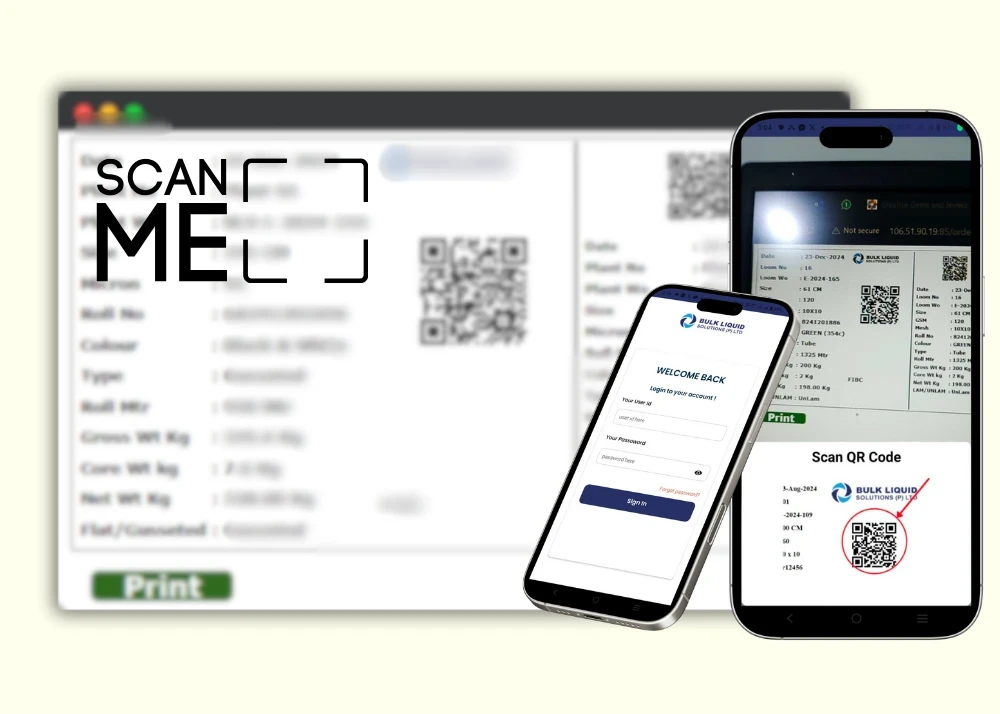

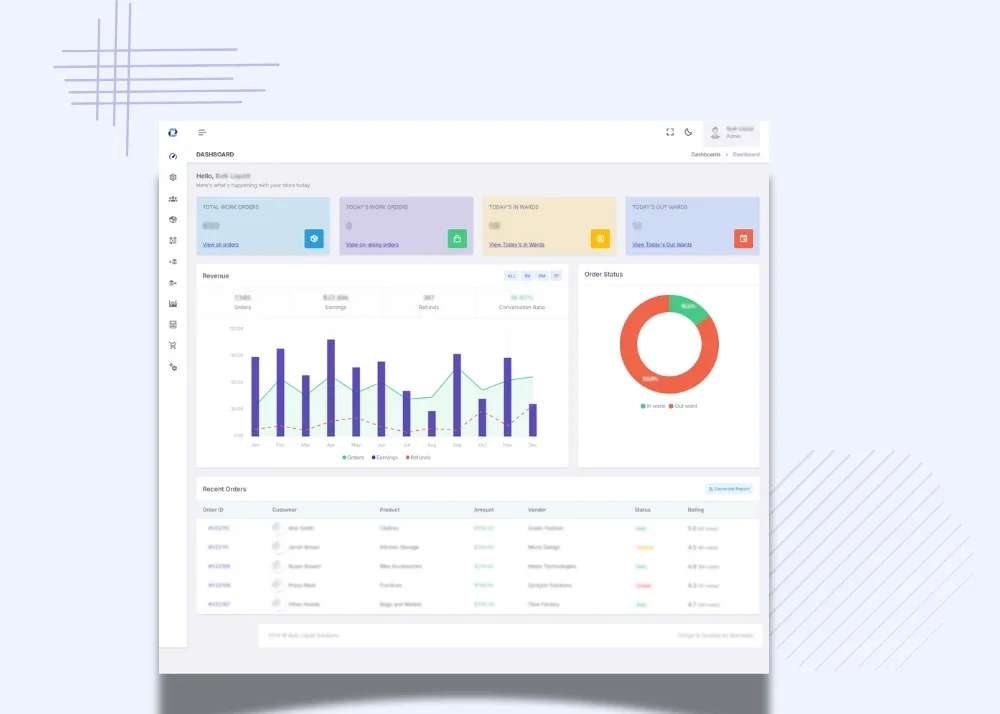

- Platform

- RFID

Software DevelopmentAssisting brands to make a digital impact.

- Offshore Software Development

- Custom Software Development

- Web Application Development

- Mobile App Development

- Full-Stack Development

- Application Migration & Re-Engineering

- Ecommerce Application Development

- On premise app development

- ERP Application Development

- CRM Application Development

- Microsoft SharePoint Customizations

- AI Development and Integration

View All ServiceYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

Web Development ServicesAssisting brands to make a digital impact.

View All ServiceYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

IT ConsultingAssisting brands to make a digital impact.

View All ServiceYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

Security EngineeringAssisting brands to make a digital impact.

View All ServiceYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

Cloud & Hosting ServicesAssisting brands to make a digital impact.

View All ServiceYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

Testing & QAAssisting brands to make a digital impact.

View All ServiceYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

Digital MarketingAssisting brands to make a digital impact.

View All ServiceYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

PlatformAssisting brands to make a digital impact.

MicrosoftOthersView All ServiceYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

RFID ServiceAssisting brands to make a digital impact.

View All ServiceYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

-

Hire Developers

- Front End

- Backend

- Software

- Security

- Other

Front EndYour trusted hiring partner.

Hire with UsYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

BackendYour trusted hiring partner.

Hire with UsYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

SoftwareYour trusted hiring partner.

- Hire SharePoint Developer

- Hire ServiceNow Developer

- Hire Salesforce Developer

- Hire SAP Developer

- Hire Office 365 Developer

- Hire Full-stack Developer

- Hire AWS Expert

- Hire Azure Expert

- Hire MEAN Stack Developer

- Hire MERN Stack Developer

- Hire MAUI/Xamarin Developer

- Hire Mobile App Developer

- Hire Software Developer

- Hire Remote Developer

- Hire Data Analyst

- Hire Data Scientist

- Hire Data Engineer

- Hire Power BI Expert

- Hire Fullstack Developer

- Hire Devops Engineer

Hire with UsYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

SecurityYour trusted hiring partner.

- Hire VAPT Security Expert

- Hire Web Application Security Tester

- Network/Infrastructure Security Tester

- API Security Tester

- Hire Certified Security Expert

- Hire OWASP Security Expert

- Hire Certified Ethical Hacker (CEH)

- Certified Security Analyst (ECSA)

- Certified Chief Information Security Officer (CCISO)

- Certified Network Defender (CND)

- Offensive Security Certified Professional

- Certified Information Systems Security Professional (CISSP) certification

- CompTIA Security+

- CompTIA Pentest+

- CompTIA Cloud+

Hire with UsYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

OtherYour trusted hiring partner.

Hire with UsYour Ideas, Our Code.Decoding challenges to reap digital brilliance.

-

Solutions

Products & Solutions by Industries

-

Technologies

Mobile Development

- Our Work

- Contact Us